“Innovation is the unrelenting drive to break the status quo and develop anew where few have dared to go.”

We’re privileged to be living in a time where science and technology can assist us, make our lives easier and rethink the ways we go about our daily lives. The exposed technologies identical to Artificial Intelligence, Augmented Reality, Robots, Metaverse, Cryptocurrencies, etc., have accustomed to has paved the way for us to innovate further. One such technology, which has the immeasurable potential to revolutionize our lives is undoubtedly 3D Printing Technology.

“The Future of innovation has to include not only technology but economic viability”

Ever wondered how Sci-Fi movies like Jurassic World managed to get their hands over the flawless shots of the extinct gargantuan like Apatosaurus, Triceratops, Mosasaurus, etc.? Such spectacular realism was only possible with the touch of 3D Scanning & Printing.

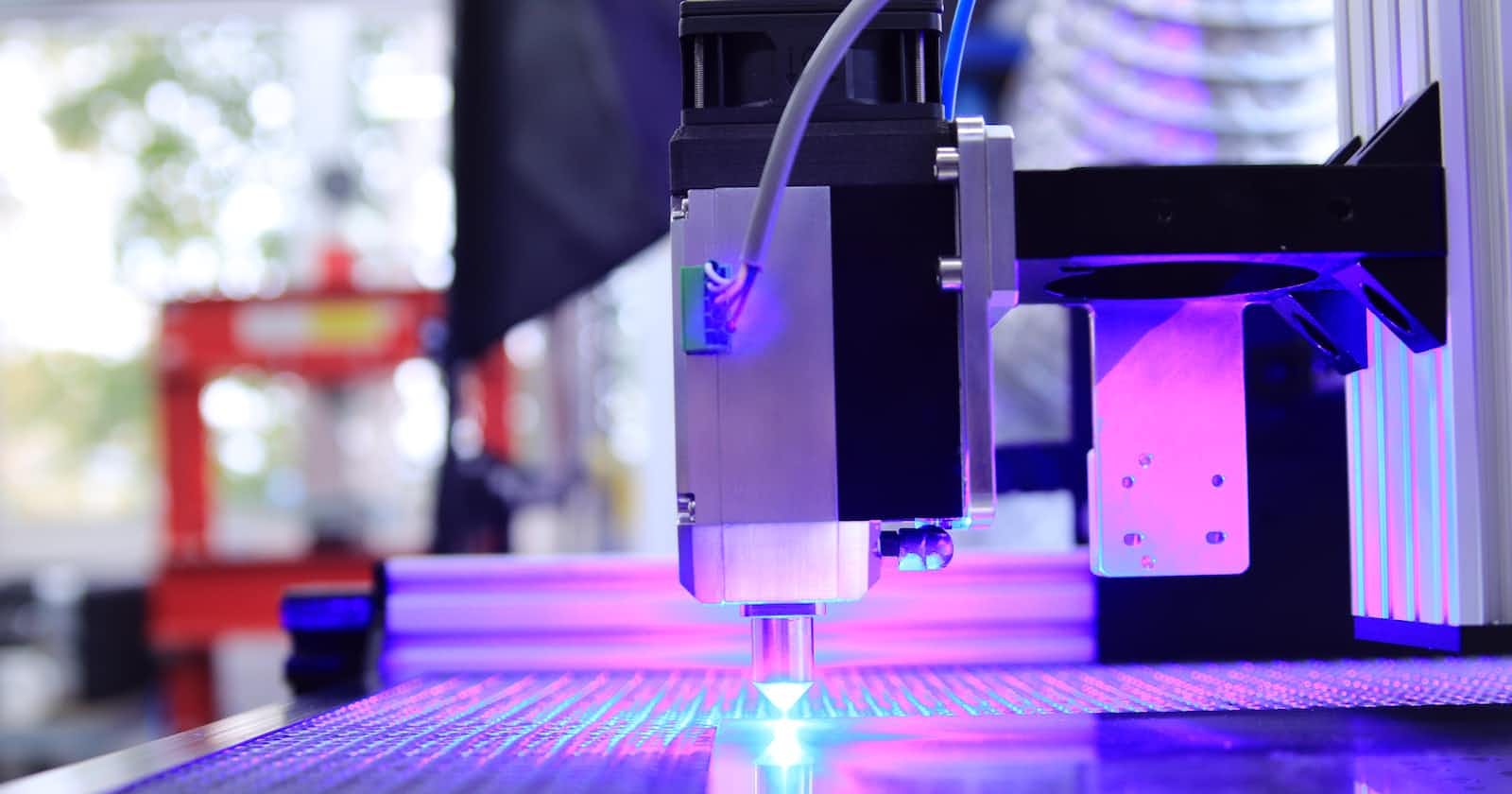

3D printing is an additive technology used to manufacture parts: from prototyping to creating lightweight geometries via a layer-stack fusion process that doesn’t involve a block of material or a mold to manufacture physical objects. Seemingly, it took birth in sync with the evolution of customers’ expectations and demands or vice versa. In recent years, 3D printing has matured into an excellent solution for many intricate production and manufacturing technologies.

Chuck Hull is typically credited with the invention of the 3D printer via his Stereolithography Apparatus (SLA) patent in 1984. During this period, multiple know-hows developed, corporations were founded and various stupendously feasible patents were submitted by scientists worldwide. The forthcoming decades witnessed swift commercialization, democratization and sooner, period of maturity where the hype around 3D printing had vanished from mass media, but the high level of interest of businesses in acclimatizing more commercial applications shot the notch.

“The future cannot be predicted, but the future can be invented. It was man’s ability to invent which has made human society what it is”

3D printing is already shaking our age-old notions of what can and can’t be made. Stephen King once said, “To write is human, to edit is divine”, but instead of the word “edit” you could substitute the phrase “3D Printing”, because this 3D expertise is playing a similarly godlike role. Today 3D printing embodies the prime industries like Architecture & Construction, Healthcare, Mechanics, Food Industry, Education, Fashion, Aeronautics, Automotive, Energy sector, etc. Apart from wide-scale usage, it also offers sterling recompenses like reduced cost, rapid manufacturing process, environment-friendly approach and improved freedom of shape.

The extensive productive efficacy is pushing the companies to use 3D technology as the capacity to cater to unprecedented circumstances such as urgency, low volume of production and the failure of other technologies in the manufacture of a complex-shaped product.

For an instance, large groups such as Boeing, SEB, Volvo and Volkswagen are embarking on such initiatives to provide customers with access to digital versions of their parts being cataloged. Other initiatives such as Boulanger in France, with their platform Happy3D, want to offer individuals to directly download spared components of their appliance, surfing the fight against planned obsolescence.

Other examples include the success in the surgical guides of humans or pets with severe internal injuries; involving the use of prosthetic limbs and models of body parts. Even Hollywood exhibits the upshots of 3D printing in its Sci-fi movies like the Avengers, Black Panther, Iron Man, etc. via the winsome wearables, weapons and 3D printed props. Also, countless fashion industries are approaching this expertise to create flamboyant aesthetics. Forget shopping, imagine soon we will be able to download our clothes!

“The secret of change is to focus all of your energy, not on fighting the old, but building on the new.”

Although 3D printing antagonizes a few shortcomings like the elevated cost at high volume production, the requirement of post-processing of printed parts, lesser product strength in comparison to the conventional manufacture and limited accuracy needs a scope aimed at improvement. But its extraordinary trump card is the adaptative & versatile nature it inherits; it can be used to create just about anything your mind can conjure up. It just requires the digital file and the right material. While experts are troubleshooting how to incorporate 3D printing processes into all areas, pacesetters are finding clever hacks to create with their 3D printers including trash cans, electric outlet plates and more! Hence, 3D printing is redefining the affluence of our lifestyle.

“Our future success is directly proportional to our ability to understand, adopt and integrate new technology into our work”